PLAYERS in the plastic industry want government to put tariffs on imports to halt the influx of cheap products that threaten the survival of the sector.

TARISAI MANDIZHA BUSINESS REPORTER

Speaking during the familiarisation tour of the plastic industry by Members of Parliament in the Industry and Commerce portfolio committee on Friday, Versapak Zimbabwe general manager Andrew John said the influx of cheap goods and the levying of duty on raw materials was killing the local industry.

“One of the challenges we are facing is duty on raw materials, it doesn’t seem like it’s a levelled playing field. The issue of imports flooding the market is killing the industry,” John said.

The committee is chaired by Ray Kaukonde, Zanu PF MP for Marondera Central.

He said the company has the capacity to produce 1 200 tonnes, but was currently producing 900 tonnes per year and capacity utilisation was between 65% and 70%.

Metal and plastic packaging manufacturer Carnaud Metalbox managing director John Van Gend said the company has been struggling with the food canning business saying it was as good as dead.

“To revive the industry, government should stop imports and there is need to grow more foodstuffs in Zimbabwe to grow the canning industry,” Gend said.

- Chamisa under fire over US$120K donation

- Mavhunga puts DeMbare into Chibuku quarterfinals

- Pension funds bet on Cabora Bassa oilfields

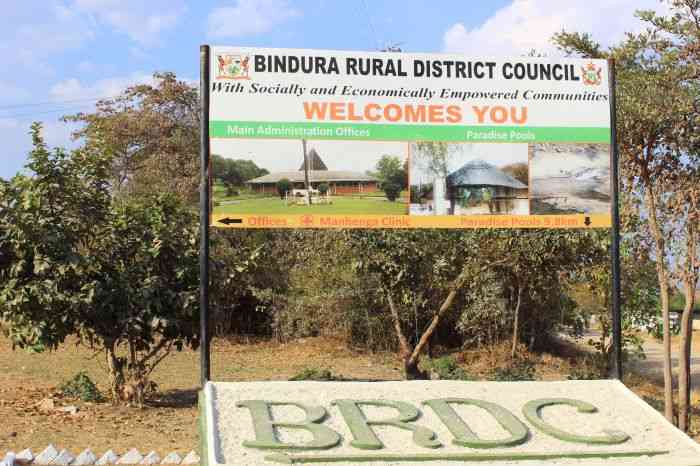

- Councils defy govt fire tender directive

Keep Reading

Manufacturers of plastic pipe systems for water and sewer reticulation, Proplastics, a subsidiary of Masimba Holdings, said the company has the capacity to produce 12 000 tonnes a year, but was currently producing 4 000 tonnes.

“The market is currently going through a tough time, low disposable income, cost per unit is low and we are not making a profit,” Masimba chief executive Canada Malunga said.

“The issue of aggregate demand requires an economic blueprint to determine how we are going to get out of it, introduction of new money as a bailout package of a substantial amount and to grow foreign direct investments.”

He said Proplastics was currently operating at 33% capacity utilisation and had a 60% market share.

Global Plastics managing director Max Chiduwa said the company was facing challenges of electricity and low demand of products due to influx of finished goods into the country.

Chiduwa said the company was only operating using four machines out of 10 due to low product demand on the market and also the high cost of running business using generators due to shortages of electricity.

“We are supposed to operate 24 hours a day and seven days a week, but due to low demand in the market we are operating four days a week,” Chiduwa said. He added that government should put in place protective tariff on imports to protect the industry.

Mega Pak marketing director Lincoln Garwi said the company was currently operating between 66% to 70% capacity utilisation and was producing 12 000 tonnes per annum.

He said the company was facing challenges of power, influx of imports and shortage of affordable credit lines.